| |

|

HVAC |

|

Machines> HVAC Machineries |

We Create Value for Our Customers

|

|

The Best World Wide

Italian Manufacturer Partner

(click here)

|

|

Asian Partner

(follow

current page)

|

|

Fin Press & Fin Die

Expander

Tube Straightener

& Cutting Machine

U Bender

Hairpin Bender

Other HVAC Machines

|

|

Fin Press & Fin Die |

|

Fin

Press line for the punching of air conditioner fins is specially

intended for meeting requirements for the production air

conditioner fins. the line mainly consist of uncoiler. oil tank,

fin press, vacuum sucker, stacker and relevant electrical

control system.

In this

production line, PLC counter and contact point free cam

controller are adapted to meet the requirements of counting the

fins cut collected as well as the function of progress change.

Production line of special specifications can be made subject to

the user's requirements.

Also required information to design a die are listed below:

Below technical data and specification are related to 450 to 800

kN fin press machine.

Please contact our technical sales engineers for further

details.

|

|

|

|

Specification |

| Nominal Pressure |

kN |

450 ~ 800 |

| Nominal Pressure

Stroke |

mm |

1.5 |

| Stroke of Slide |

mm |

40 |

| Strokes |

SPM |

100-180 |

| Max Dia. Set

Height |

mm |

270 ~ 290 |

| Dia. Height

Adjustment |

mm |

70

~ 80 |

| Depth of Throat |

mm |

300 |

| Distance Between

Uprights |

mm |

510 ~ 600 |

| Size of Table |

mm |

800×580 ~ 900×580 |

| Thickness of Table |

mm |

80 ~ 100 |

| Bottom Size of Slide |

mm |

500×300 ~

600×350 |

| Hole for Punch Chank

(dia Depth) |

mm |

50×60 |

| Overall Dimensions |

mm |

6500×2500×3000 |

| Mounting Size of

Foot Bolt |

mm |

760×1090 ~

670×1340 |

| Air Pressure |

MPa |

.5 |

| Total Weight |

kg |

600 8500 |

| Max. Allowed

Engaging Time at Single Operation |

|

15 |

| Width of Material |

mm |

300 |

| Stack Lenth |

mm |

800-1000 |

| Collecting Height of

Material |

mm |

600 |

| Inner Diameter of

Material Rolling |

mm |

75 |

| Outer Diameter of

Material Rolling |

mm |

850 |

|

|

Complete

technical data and specific characteristics of our Fin Press machines are listed in our quotation. Please contact our

technical sales engineers for further details. |

|

|

|

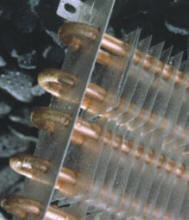

Expander

Vertical, Horizontal, Portable

|

Expanding of

coils is one of the most diversified areas in coil manufacturing.

Huge variety in coil dimensions, different tube materials, such as

aluminum, copper, steel and stainless steel, different tube

thickness. Each of these variables demanding a different solution. Expanding of

coils is one of the most diversified areas in coil manufacturing.

Huge variety in coil dimensions, different tube materials, such as

aluminum, copper, steel and stainless steel, different tube

thickness. Each of these variables demanding a different solution.

Starting from a single tube expander up to a multi-rod expander,

400 rods. Possibility to have a fully automatic control:

automatic height set-up as well as single rod selection.

On

the multi-rod vertical expander, equipped with NC, the set-up

time has been reduced to less than 5 minutes, offering the

highest flexibility on the market.

Required information to choose an expander are listed below:

-

Machine Type (Portable, Vertical or Horizontal)

-

Effective Length (Horizontal) or Height (vertical)

-

Layout Pattern (Staggered, Parallel)

-

Number of Rows & Holes

-

Tube Diameter

-

Control System (PLC, Auto Traditional)

|

| |

|

Tube Straightener

& Cutting Machine |

Automatic

machines to straighten and cut tube wound in coils, for the

production of heat exchanger coils. Tube feeding is performed by

a suitable unit: the tube is brought to the required length and

then cut with an orbital cutting system that yields a burr-free

cut. Automatic

machines to straighten and cut tube wound in coils, for the

production of heat exchanger coils. Tube feeding is performed by

a suitable unit: the tube is brought to the required length and

then cut with an orbital cutting system that yields a burr-free

cut.

Required information to choose this machine are listed below:

-

Maximum Cutting Length

-

Tube Diameter

-

Tube Thickness

-

Material

-

Number of Cutting per Cycle plus extra Dies for Other Tube

Diameters

-

Control System (PLC, Auto Traditional)

|

| |

|

U Bender |

|

Fully

automatic machine to manufacture return bends, straight and

elbows starting from copper tube in coils.

As option the machine can be

equipped with extra tools for cross-over production. The machine

is supplied with a soundproof cabin, in full accordance with

international Safety Standards.

Required information to choose this machine are listed below:

-

Tube Diameter

-

Tube Thickness

-

Material

-

Pitch (Center to Center of Tube)

-

Number of Tubes per Cycle plus extra Dies for Other Tube

Diameters

-

Height of U

-

Control System (PLC, Auto Traditional)

|

| |

|

Hairpin Bender |

Machine is equipped

with a 3 tube tooling for 3/8" tube, a 2-tube tooling for 5/8"

tube and 2-tube tooling for 1/2" tube.

Required information tchoose this machine are listed below:

-

Length of Total Tube

-

Length of Bended Part

-

Tube Diameter

-

Tube Thickness

-

Material

-

Pitch (Center to Center of Tube)

-

Number of Tubes per Cycle plus extra Dies for Other Tube

Diameters

-

Control System (PLC, Auto Traditional)

|

| |

Other HVAC

Machines

are available according to the customer's request

|

|

Coil

Bending m/c

O-Ring

Making m/c

O-Ring

Inserting m/c

De-Burring m/c

Automatic Hair Pin Bender m/c

Punching m/c for End & Side Plates

Automatic brazing m/c |

|